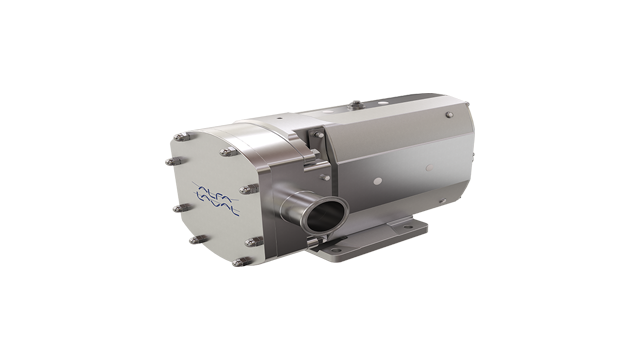

CM

Maximize plant uptime while minimizing costs with the Alfa Laval CM, a wireless vibration monitoring system that tracks the operating condition of pumps. Compact and easy to use, the CM condition monitor supports decision-making to protect valuable plant assets. A sensor measures vibration and alerts operators through a visible LED indicator on the monitor and any connected mobile device within range if preset thresholds are exceeded.

More process uptime with remote monitoring

- Condition monitoring for fast and accurate response

- Minimal unplanned downtime

- Low total cost of ownership

- Easy to install, operate and maintain

- Improve worker safety

Let the Alfa Laval CM take condition monitoring to the next level using advanced data on vibration, temperature and run-time to keep track of equipment condition and ensure process continuity.

The CM condition monitor collects and analyzes data from rotating machines, recording any deviation from benchmark performance. Based on the data, the operator can make fast, accurate decisions and schedule maintenance accordingly, preventing potential problems before they occur. This maximizes uptime, increases efficiency, reduces the risk of equipment failure and lowers your total cost of ownership.

The Alfa Laval CM condition monitor is suitable for use in the dairy, food, beverage, home-personal care, biotech and pharmaceutical industries.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Machine condition monitoring

Monitor and record the vibration, relative temperature and run-time of your rotating equipment. Initially, the CM was optimized for use with Alfa Laval pumps. The condition monitoring equipment records data at preset intervals and maps trends so you can schedule maintenance based on the actual condition of your equipment. This ensures sound asset management and process continuity.

Proactive equipment health checks

Monitor pumps from your iOS or Android smartphone or tablet using the free mobile app during routine plant walk-arounds. A visual LED indicator also provides visible notification of the operating status of a machine. This enables maintenance technicians to make the best use of their time while focusing on maximizing equipment uptime.

Informed decision-making

Using the CM condition monitor with its intuitive machine learning techniques helps operators make maintenance and process shutdown decisions based on actionable information, including actual runtime, trend analysis, and time to next service.

Ensure worker safety and productivity

Enabling reliable and secure remote monitoring of your equipment and systems contributes to worker safety. Remote troubleshooting also increases worker productivity and efficiency while significantly reducing maintenance costs.

Easy to install, easy to use

Setting up and using the battery-driven condition monitor is easy. It communicates via Bluetooth to an intuitive app and transfers data to a user-friendly dashboard on any iOS and Android device.

Sensors

Monitor vibration, device temperature and run-time hours.

Mobile app

Remote on-premises equipment monitoring from any iOS or Android device

Dashboard

Easy-to-use intuitive control panel to track vibration, temperature, run-time and battery status

How does the Alfa Laval CM condition monitor work

The Alfa Laval CM condition monitor uses a three-axis accelerometer and internal temperature sensor to collect and store machine data. The condition monitoring equipment activates when it senses vibration and starts the run-time counter. It then continues to monitor the tri-axial vibration and device internal temperature 24/7 at pre-set intervals determined by the user.

Simply download the intuitive, user-friendly app to enable users within 20 metres of the CM to access data via Bluetooth Low Energy (BLE) on their iOS or Android devices. An easy-to-use dashboard lets users review vibration data converted using fast Fourier transform (FFT) algorithms, compare the current operating condition with benchmark values, and determine actions to address any issues in order to prevent equipment failure.

The app displays CM battery status, historical data for machine vibration and internal temperature, total run-time, and detailed machine information such as vibration levels and frequency analysis. Users can also find and contact service partners through the app.

Join us on the journey to Industry 4.0,, where digitalization and human-machine interaction can further optimize your processes.

To download the Alfa Laval CM app scan the QR-code or click the download button.

Happy customers

Condition monitoring prevented the product loss of 288,000 bottles at Britvic facility

The user-friendly and cost-effective Analytics for online condition monitoring brought peace of mind and enabled Britvic to maintain pumps at their peak performance during 24/7 production

You might also be interested in…

Alfa Laval Analytics

Alfa Laval Analytics is a leading, AI-based solution for online condition monitoring. Analytics helps you detect potential machine failure before it occurs and diagnose the root cause. The user-friendly and affordable solution brings peace of mind and helps keep your pumps at peak performance at all times.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.